Dynamic balancing of fans has long ceased to be a simple procedure. Today, this is a key factor in the reliability, efficiency, and safety of equipment. A rotor with an uneven mass distribution creates centrifugal forces that cause vibrations, noise, and excessive stress on the bearings. The system is losing stability, and maintenance costs are rising. Balancing reduces fluctuations, extends service life and reduces energy consumption. Regular performance of the procedure makes the operation of the fans quieter, more stable and cheaper.

Proven Benefits of Proper Balancing

Practice confirms that properly performed balancing reduces the vibration level to ISO standards. After the two-plane correction, the amplitude drops noticeably at a frequency of 1X, and the fan is more stable. This reduces the number of emergency stops and increases the life of the equipment.

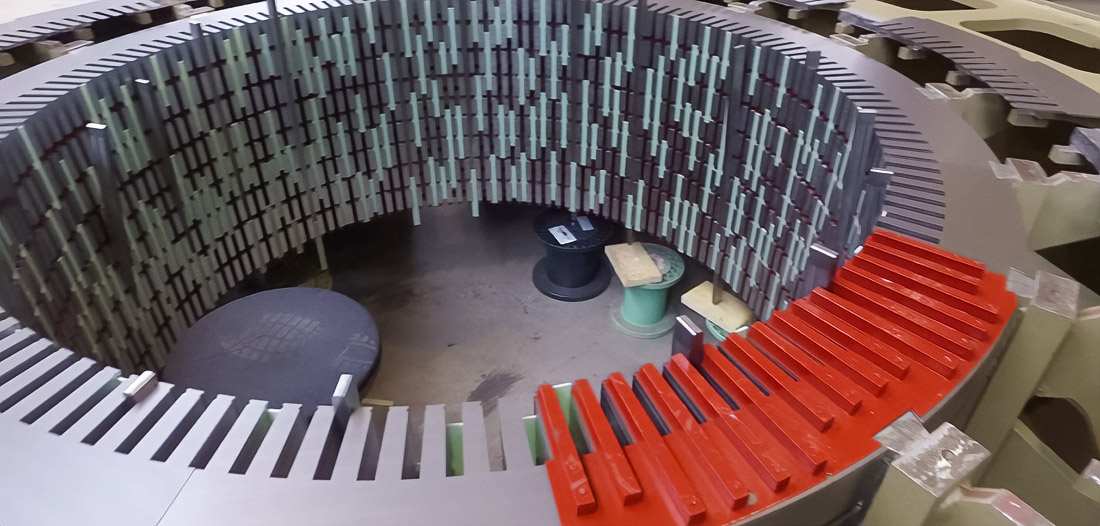

Balancing methods are diverse: single-plane, two-plane, and multi-plane. Small impellers require only one plane, large rotors require two, and complex designs require adjustments at several levels. The work is carried out in a workshop or on site using laser systems and vibration diagnostic devices. For impellers up to 2 m in diameter and weighing up to 50 kg, quality is achieved according to ISO 1940-1, class G6.3, at a test speed of at least 800 rpm.

Energy Savings and Environmental Impact

The balancing effect goes beyond mechanics. There is a direct relationship between fan speed and power consumption. Reducing the speed by only 20% reduces consumption by almost 50%, because the power is proportional to the cube of speed. In HVAC systems, adjustable drives provide savings of 20 to 50%. The average payback period for investments is 1.5–3 years, less often it reaches 5 years. The more often the system operates in alternating mode, the faster the invested funds are returned.

Balancing is also of environmental importance. It reduces noise, improves the working conditions of personnel and increases the stability of the structure. In cooling towers and air treatment plants, balanced fans preserve the life of bearings longer and require fewer repairs. This directly reduces costs and makes operation more predictable. For any electro mechanical company involved in HVAC, maintenance, or energy optimization, these results highlight the necessity of balancing as part of long-term strategy.

Regular balancing is a necessity. It prevents breakdowns, prolongs the life of the fans and reduces the risk of accidents. In combination with variable frequency drives, balancing becomes a strategic energy management tool. This solution is both technical, economic and operational, the importance of which cannot be overestimated in modern cooling systems.

I am a Web Developer. I like to hike, crochet and play video games with my son.